Indianapolis has a long history of industry and manufacturing, which persists today. In the 1870s had already made Indianapolis a hub of commerce and transit. In 1872 local businessman Frederick Ruschaupt and several others started the Indianapolis Car and Machine Works on a plot of land in the neighborhood on the northeast side of Indianapolis. Two years later the Indianapolis Car and Machine Works reorganized as the Atlas Works. Another reorganization in 1878 resulted in the formation of the Atlas Engine Works, an entirely distinct corporation that shared none of the same shareholders as the Atlas Works. The sole connection between the companies involved Atlas Engine Works renting the property from Atlas Works.

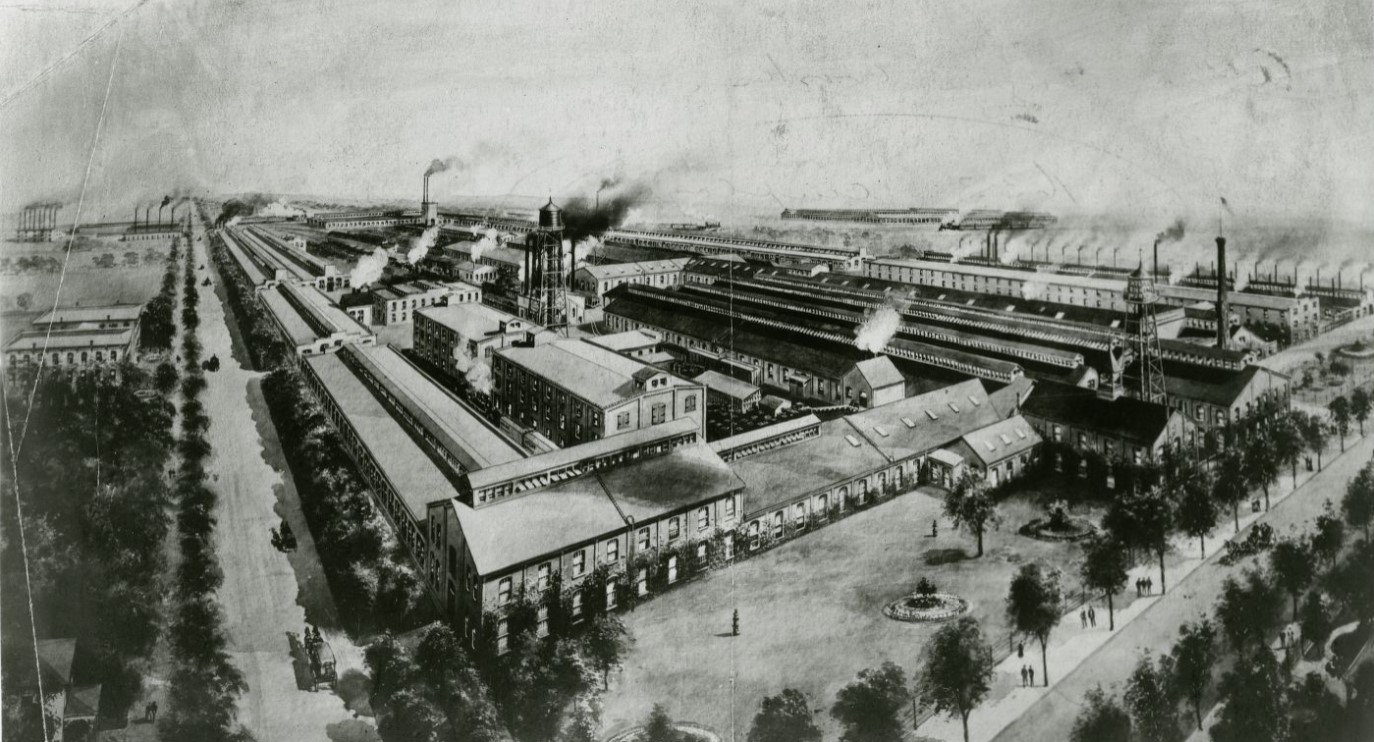

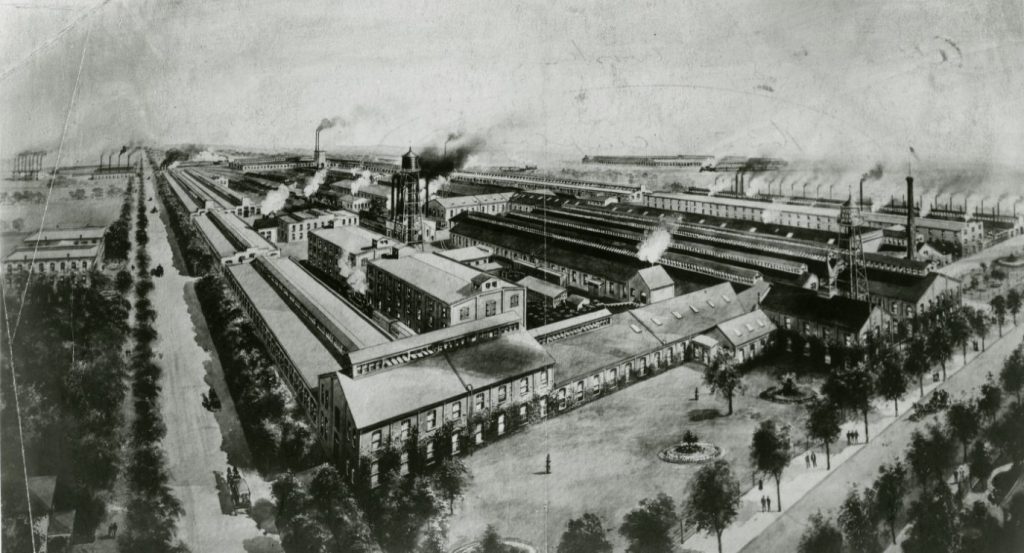

Atlas Engine Works built a large industrial complex dedicated to the construction of railcars which occupied 65 acres of land. This included a connection with the Belt Railway around the northern border of Indianapolis of which almost 7 miles of track ran into the complex. It was so massive that a railroad flat car was lost inside the complex for several days before workers found it. A drainage channel called the State Ditch ran along the western boundary of the complex.

, son of , became president of Atlas Engine Works in 1878, a position he maintained until he died in 1895. Fletcher’s experience in numerous business endeavors, including serving as a railroad conductor and engineer for the Indianapolis Bellefontaine Railroad, a farmer, a banker, and president of the Indianapolis Gas Light and Coke Company (predecessor to ) made him a logical candidate to operate the business.

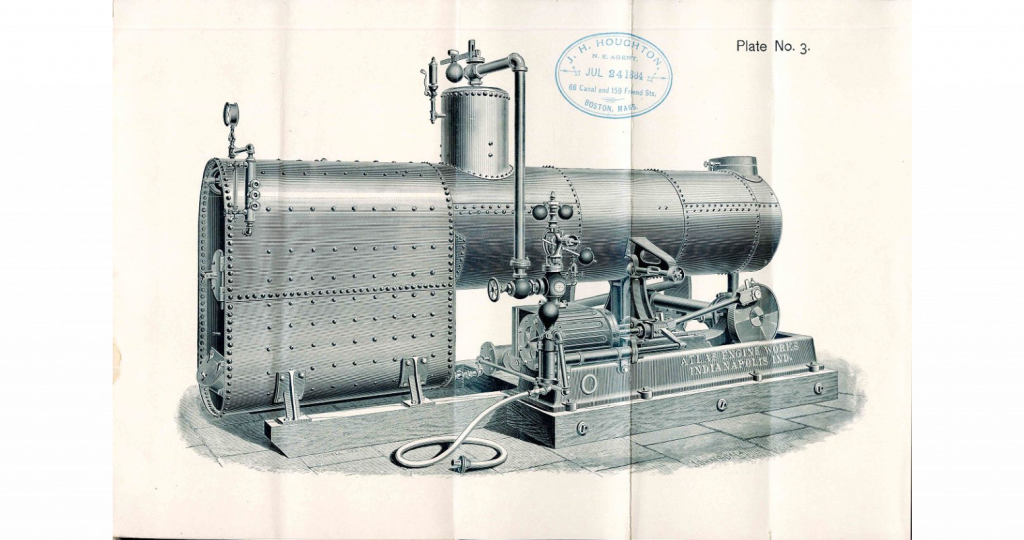

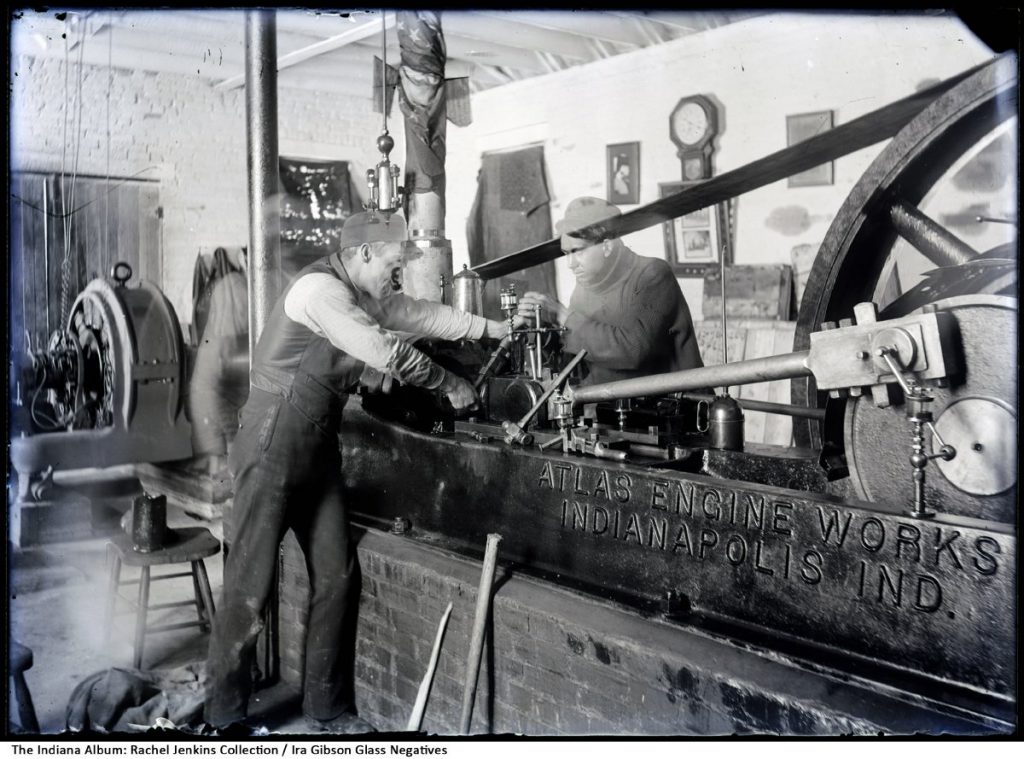

During the transition time between the closure of the Indianapolis Car and Machine Works and Fletcher’s presidency of Atlas Engine Works, the business responded to orders for miscellaneous equipment with no standardized product. In 1880 Atlas Engine Works focused on the construction of stationary and mobile steam engines and boilers, most often for industrial use in factories and mills, in addition to a variety of parts for the engines and other machines. The company modified the manufacturing process into a standardized process resembling that of an assembly line in 1902. The company described the process as “repetitive construction, with interchangeable parts; the manufacture of engine and boilers in lots instead of one at a time, and the carrying of large stocks of manufactured merchandise.”

By 1881, the company specialized in manufacturing the Atlas-Corliss engine, a type of steam engine that inventor George Corliss patented in 1849. The engine, built with 50 to 1,000 horsepower, had a variety of industrial uses. Atlas Engine Works would later expand its product line into gasoline turbines and engines, automobile components, and tractor engines.

In June 1884, Fletcher & Sharpe Bank of Indianapolis announced its failure amid the Depression of 1882-1885. The bank owned the land upon which the Atlas Engine Works sat. To generate funds to pay its creditors, Fletcher & Sharpe Bank sold the property it had leased to Atlas Engine Works for $75,000 in 1887.

Former general manager of Atlas Engine Works, Hugh H. Hanna became owner of the firm by 1901. Under his aegis, the company doubled its manufacture of finished products after the construction of new, modern facilities to accommodate the increased output of engines and boilers for domestic and global trade. The number of employees increased from roughly 1,100 to 1,800. These men manufactured 24 boilers of 125 horsepower each day.

Despite the success of the Atlas Engine Works, especially in global trade, shrinkage in domestic trade and shifts in the national economy at the turn of the 20th century spelled trouble for the firm. Crop failures, a drop in cotton prices, reckless railroad speculation, and unexpected plunges in the stock market converged at different times to send the growing economy into a tailspin. In 1903, the reported that Atlas had laid off “several hundred” employees, mostly laborers but also skilled tradesmen.

By 1908 Atlas Engine Works experienced reduced activity and fell into court receivership after a Chicago bank filed suit against the company in Marion County Superior Court alleging insolvency resulting from certain creditors taking control of the business and using corporate funds toward their debts while excluding the Plaintiff bank and other creditors. In addition to the lawsuit, Atlas Engine Works faced a scandal after allegations arose of company representatives and officers offering and making bribes to Indianapolis and Marion County officials to secure contracts.

In July of 1912, two creditors sought a second receivership against the company after alleging insolvency. Atlas Engine Works owed the two approximately $2,300. The Indianapolis News reported the company had a large amount of inventory but awaited payments from an automobile manufacturer which hampered its ability to pay the two creditors.

In October of 1912 Chicago-based James W. Lyons purchased the Atlas Engine Works. Operating as the Lyons Atkins Company, the firm remained in operation until 1917 when it merged with other companies. Following the receivership in 1912, Atlas Engine Works spun off its gasoline turbine arm and sold it to a firm in San Antonio, Texas which operated as Krueger Atlas Company.

The property where Atlas Engine Works once sat became home to many companies that produced a variety of industrial goods, including auto parts for nearly a century. Ertel Manufacturing Corporation operated at the property until it shut down in the early 2000s.

After 130 years of industrial use, environmentalists consider the property a due to the heavy concentration of pollutants in the soil. In 2017 the Environmental Protection Agency (EPA) conducted an emergency clean up and the city of Indianapolis took over the property. Ultimately, the EPA removed 55,217 tons of contaminated soil from the site. Following the cleanup and demolition of most of the older structures at the site, Major Tool & Machine, Inc. constructed new facilities and continues to operate there as of 2023.

At its height, Atlas Engine Works employed more than 2,200 laborers and skilled tradesmen. These workers built over 35,000 steam engines during the life of Atlas Engine Works.

Help improve this entry

Contribute information, offer corrections, suggest images.

You can also recommend new entries related to this topic.