The history of the Chrysler Corporation in Indianapolis began in a relationship with the American Foundry Company, which was established in 1890 and incorporated in 1901. During the 1910s, American Foundry produced engine blocks and heads for early automobile manufacturers, including Indianapolis-based and . The foundry also produced engine blocks and heads for Maxwell Motor Company, the forerunner to Chrysler Corporation.

Unlike the early automobile companies that operated in Indianapolis, Maxwell responded to the challenges that the Ford Motor Company presented when it began producing lower-priced automobiles. It introduced its Model 25 to compete with the Detroit automaker. Nevertheless, Maxwell struggled in the post-World War I depression, and Walter Chrysler reorganized and took over the company. In 1925, Chrysler formed his own company Chrysler Corporation, which absorbed Maxwell. That same year, the American Foundry began supplying engine blocks to the new company.

American Foundry produced engine blocks at its first location on South Warman until a fire destroyed it in 1930. It then operated on Naomi Street until 1944. Two years later, Chrysler purchased the Naomi Street foundry along with its scrapyard and incorporated the inactive company in the same name as had its former owners. American Foundry operated as a Chrysler-owned subsidiary and made nothing except engine blocks for the parent company.

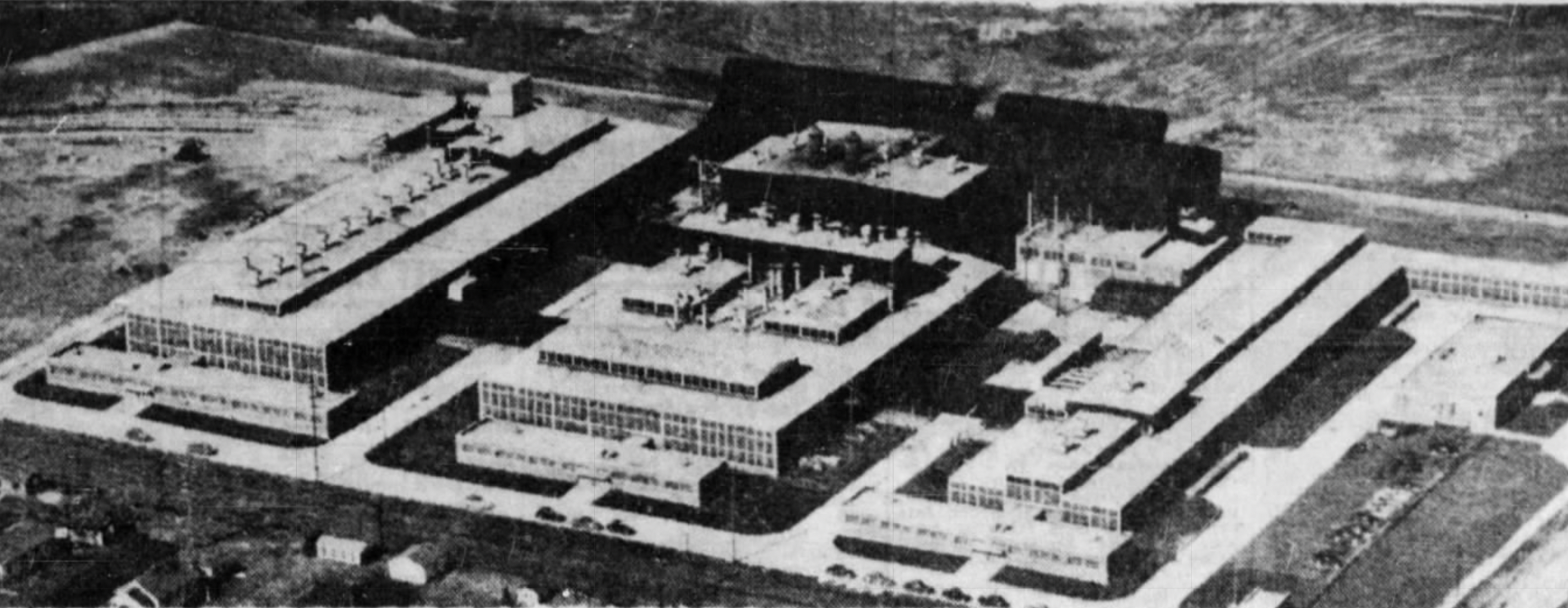

In early 1950, Chrysler built a new American Foundry plant on Tibbs Avenue. The new plant cost $15 million (around $160 million in 2020). At the time, the Tibbs Avenue factory presented the state of the art in automobile manufacturing. It could produce twice as many auto engine heads (400 tons) a day as did other plants. Chrysler also kept the Naomi location running. Construction of a Shadeland Avenue factory began in 1950 and, after changes of plans, production of automobile transmissions started in 1953.

In January 1959, Chrysler housed its new Electrical Division at the Shadeland Avenue location. Distributors, starters, and other electrical parts for cars became the plant’s focus. The main plant occupied about 80,000 square feet. A parts depot was built nearby.

American Foundry merged formally with Chrysler in 1959. By 1964, it had 1,300 employees and operated at “peak levels.” Chrysler made a $3 million expansion to the plant, which increased metal-melting capacity for creating engine blocks by 50 percent. With the expansion, the Tibbs Avenue plant became the largest foundry in Central Indiana. The factory produced all V-8 engine blocks for Chrysler cars. Chrysler quietly abandoned the Naomi Street plant, which had become outdated and obsolete, sometime in the 1970s.

Employment reached 3,500 at the Shadeland Avenue plant in the 1970s but had shrunk to 1,200 in 1987 when plans were announced to close the plant because of its obsolete tooling and dated and expensive product line. Most employees were transferred, but Chrysler, which had recently paid back a $32 million loan from the State of Indiana and had borrowed $3 billion on guarantees from the federal government, received much criticism.

In 1996, Chrysler announced a $225 million upgrade project for the westside foundry. The expansion, designed to boost efficiency and reduce air-pollution emissions, included a 114,000-square-foot core building, a 36,000-square-foot cleaning room, and a 6,000-square-foot melt system. This expansion made the Tibbs Avenue plant the “world’s largest core installation” for the manufacture of cylinder blocks. The new facility produced engine blocks and other components for Chrysler trucks and sports utility vehicles.

In 1998, the German automotive giant Daimler-Benz merged with Chrysler to form the $32 billion DaimlerChrysler AG, expecting to become a much stronger player in both the European and American markets. With upgrades, the Tibbs Avenue plant improved productivity and had an excellent environmental record between 1998 and 2002.

When the president of Chrysler, Dieter Zetzche, visited the foundry in 2002, he complimented workers and stated that he had no plans to close the plant. But the company was losing approximately $3 billion annually. In June 2003, the company projected a $1.78 billion loss for the quarter. On September 16, 2003, Chrysler announced that Tibbs Avenue plant and its 1,000 workers would be phased out over the next four years and the plant shuttered. By the time of the announcement, the factory was one of the only foundries owned by an auto company in the United States. The foundry produced its last engine block on September 30, 2005, when it closed and idled 900 workers.

Help improve this entry

Contribute information, offer corrections, suggest images.

You can also recommend new entries related to this topic.