Allison Transmission is a major producer of aircraft engines. , a founding partner of the Company and the , established the Allison Speedway Team Company, a machine shop, in 1913. It was renamed the Allison Engineering Company in 1917. The firm began supplying tools, jigs, fixtures, and gauges initially to the for use in the World War I Liberty engine. Allison received additional contracts for production models of superchargers, whippet tanks (British tanks), and high-speed tractors.

After the war, the Army awarded Allison a contract to redesign and retool 3,000 surplus Liberty engines to improve their reliability and life. This resulted in the development of a steel-shell bearing with lead-bronze lining, a remarkable product that revolutionized the aircraft engine industry throughout the world and became the most profitable product of the company. By 1927, Allison’s major products, in addition to its bearings, were airplane reduction gears and high-speed superchargers.

After the death of James Allison, General Motors purchased the company (1929) for $592,000. During the early 1930s, the company began experimental development on a revolutionary idea, a 1,000-horsepower reciprocating, liquid-cooled aircraft engine, which would have a slimmer shape than an air-cooled engine, for use in military aircraft. On April 23, 1937, the engine, designated as the V-1710, passed all the tests required by the Army Air Corps to become the first aircraft engine in the United States qualifying at 1,000 horsepower.

Early in 1939, the War Department awarded Allison a $15 million contract for 524 V-1710 liquid-cooled reciprocating engines. This engine was so successful that the Allison Company received additional contracts from the United States as well as from Britain and France during World War II. Near the end of the war, the company received a contract for the development and production of turboprop engines. Allison’s total production for the war effort was 70,000 engines, both reciprocating and jet, and 10 million bearings. At its peak in 1943, the plant employed some 23,000 persons working three shifts seven days a week.

The physical size of the company also grew from one machine shop to three modern factory buildings, giving the company a total floor space of 3,843, 690 square feet by 1943 as well as 17 specially designed test cells for testing the new jet engines. An additional plant was built in 1951, at which time the Aeroproducts Propeller Company of Dayton, Ohio, became consolidated with Allison.

Allison entered the diesel industry in the late 1940s when it began providing bearings and gears for locomotives manufactured by General Motors’ Electro Motive Engineering Corporation. Shortly thereafter, General Motors moved its Transmission Engineering Section from Detroit to Indianapolis. As a result of this move, Allison Engineering was divided in 1946 into two General Motors operating units, Aircraft Operations and Transmission Operations.

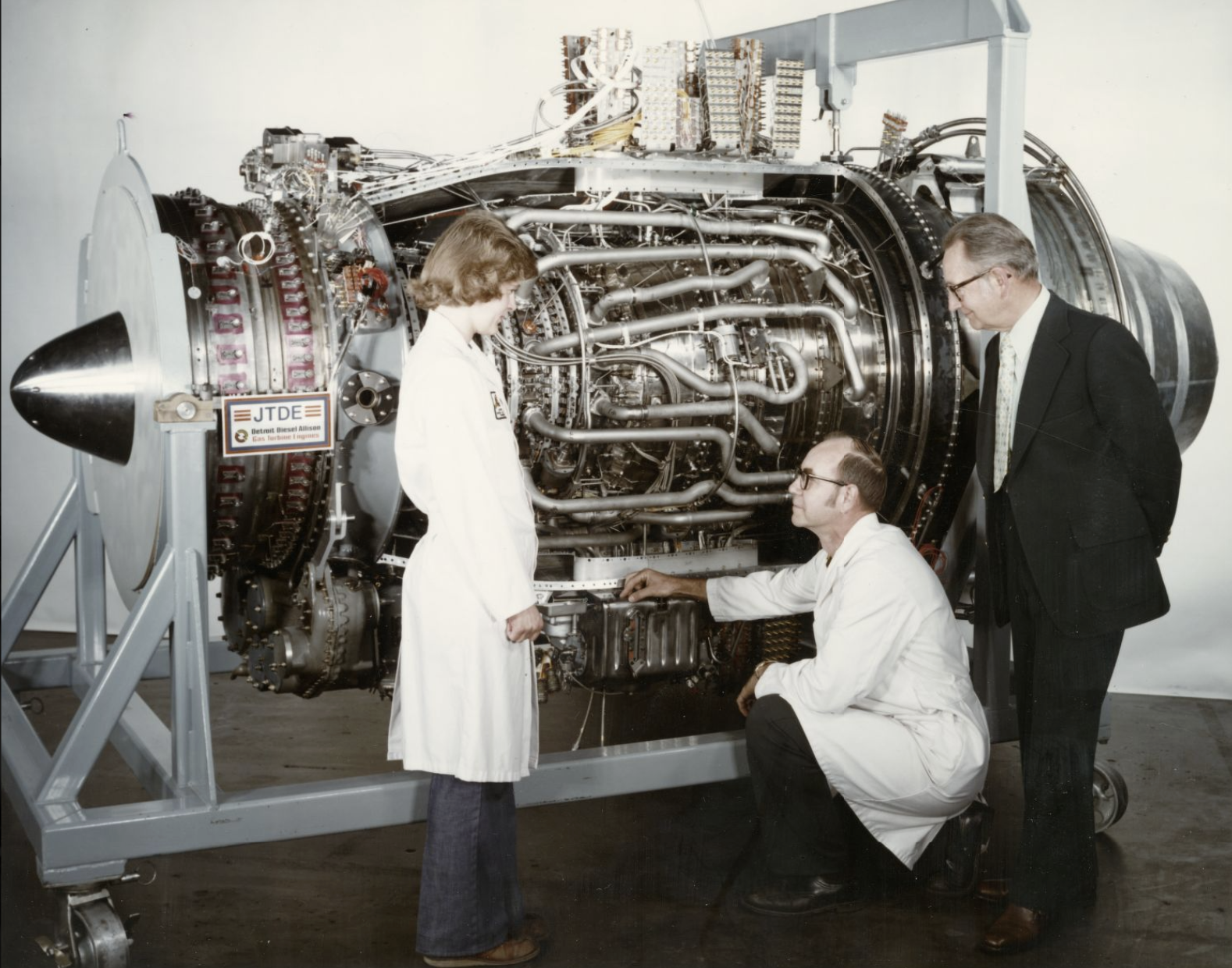

In 1970, General Motors’ Michigan-based Detroit Diesel Engine Division was consolidated with Allison Operations, which became Detroit Diesel-Allison and combined the production and development of diesel engines and transmissions with gas turbine engines. General Motors believed this merger would give Allison additional stability. General Motors’ commitment to the increasingly strong diesel market, however, left Allison’s position weak and insecure in the business world.

It was not until 1983 that the Detroit Diesel Allison Operations and Transmission Operations were reorganized into two separate divisions, Detroit Diesel Allison Division (DDA), which included the transmission operations of Allison, and Allison Gas Turbine Division. The transmission portion of DDA was growing strong, though it was not being recognized by the diesel-dedicated corporation. Detroit Diesel began having problems and General Motors finally sold the diesel portion of the business to Roger Penske. GM retained the transmission portion, however, and in 1987 established it as the Allison Transmission Division.

By the early 1990s, the machine shop that James Allison began had become two distinct General Motors divisions, Allison Gas Turbine Division and Allison Transmission Division. Both units faced an uncertain future as General Motors placed both divisions up for sale in 1991 in order to concentrate on the automotive business.

In November 1993, GM called off its sale of Allison Transmission to the German firm ZF Friedrichshafen AG following a suit by the U.S. Justice Department, which claimed that it would dampen competition. On December 1, 1993, Allison Gas Turbine became Allison Engine Company following a reported $310 million sale to senior Gas Turbine managers. The company, with annual sales of about $700 million, employed approximately 4,700 at the time of the sale, down from 6,000 in the late 1980s.

However, a few years later in 1995, Rolls-Royce purchased the Allison Engine Company for $525 million. Using the momentum from this sale and the success of the Allison Engine Company, Rolls-Royce used its new subsidiary to maintain a large presence in the Indianapolis area well into the 21st century.

Meanwhile, the Allison Transmission Division remained with GM at the turn of the century. In 2007 Allison Transmission finally was sold to two private equity firms, The Carlyle Group and the Onex Corporation. While the sale meant leaving the GM system, Allison has nevertheless worked closely with GM in the years following the sale.

In addition, the early 21st century saw Allison Transmission (the name by which it became recognized following the sale) begin to expand beyond Indianapolis. For instance, the company opened a customization center in 2005 in Shanghai as well as a manufacturing plant in 2010 in Chennai, India.

Allison Transmission continued to innovate at home as well, launching a hybrid electric program that required the opening of a hybrid manufacturing plant in Indianapolis in 2010. As of 2020, Allison Transmission employed roughly 2,900 people worldwide, including 2,600 in Indiana.

Allison opened its Vehicle Environmental Test Center in 2020. When electric-vehicle testing capabilities were added to this facility in 2021, it became known as the Vehicle Electrification and Environmental Test Center. In March 2022, the company opened its $400 million Innovation Center. The center provides a home for about 300 Allison engineers, designers, and others who worked previously at other company sites. It features a 3D printer in-house and virtual-reality and mixed-reality technologies. These virtual- and mixed-reality technologies allow users to examine Allison components virtually, providing an alternative to the physical disassemblement of the actual component.

Help improve this entry

Contribute information, offer corrections, suggest images.

You can also recommend new entries related to this topic.