Blacksmiths and toolmakers were some of the earliest metal workers in Indianapolis. They shod horses, manufactured agricultural implements, and forged iron tools for the agrarian economy. By 1835 Robert Underhill established a successful iron foundry at Pennsylvania and Vermont streets which produced plows, andirons, and skillets, and later cast-iron products, steam engines, and parts for railroad cars. With the arrival of the in 1847 the city’s previously limited markets became much more accessible. Metal-related enterprises, in turn, increased dramatically as Indianapolis responded to the railroad industry’s need for iron products and repair facilities.

Attorney noted in October 1852, that “some 5 or 6 machine shops and foundries” were in the city. The in November 1852, reported that these new establishments, “which employed some two hundred men,” had increased Indianapolis’ population and its contribution to the industry. Among the principal manufacturers of the period were the Eagle Machine Works (threshing equipment and agricultural implements), the Washington Foundry (steam engines and threshing machines), along with other machine works, boilermakers, and stove manufacturers. Although it initially floundered, the Indianapolis Rolling Mill, which began shaping iron railroad rails in 1857, became an important industry within a decade.

By the 1860s, iron manufacturers constituted the largest of all Indianapolis industries in capital invested, number of workers, value of product, and value added. The local economy supported blacksmiths, wagon makers, machine shops, a stove manufacturer, and toolmakers. In response to the , a cartridge production facility was set up on the State House grounds. Work began in April 1861, to supply Hoosier troops, as well as those from other states, with ammunition. The next year the arsenal moved to East Washington Street. The 1870s showed continued diversification of the city’s iron industries, with several new ventures including a pump manufacturer, brass works, tinware shops, plow makers, lightning rod manufacturers, railroad car production, hardware manufacturers, and a lamp maker.

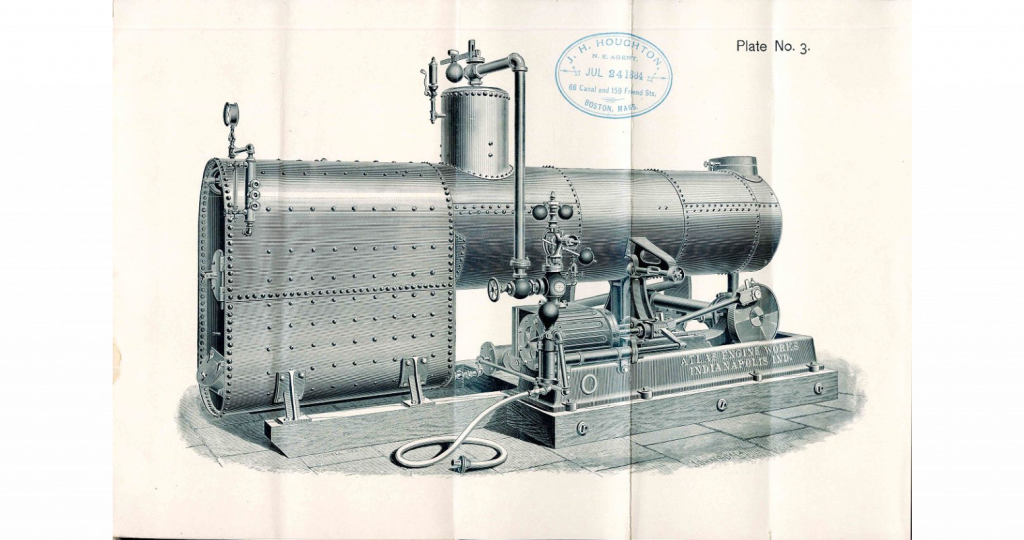

During the ensuing decade industrialization increased rapidly. The 1880 manufacturing census recorded that the city’s iron- and steel-related industries produced over $3.8 million worth of products and employed over 2,200 people. By 1884 Indianapolis boasted 48 blacksmiths, 14 tinware manufacturers, 4 ornamental iron works, several copperware makers, and a cutlery specialist. Numerous metal-related businesses began or expanded operations during this decade, including E. C. Atkins and Company saw works, Parry Manufacturing, Indianapolis Frog and Switch Company, National Malleable & Steel Castings Company, Pioneer Brass Works, Atlas Engine Works, William Langsenkamp’s copper business, and C. & G. Potts & Company, an iron and steel foundry. , which specialized in gristmill machinery, employed 300 people and reported annual production worth over $600,000. By this time many of the companies recruited and employed immigrants to work in the factories, thereby contributing to the rapidly growing economy as well as to the emerging ethnic enclaves surrounding the places of employment.

Indianapolis again proved important in the transportation industry in the 1890s, producing both bicycles and bicycle parts at nine local shops. By the early 1900s the city’s automobile manufacturers such as Cole, , and had become principal consumers of metal and metal products. The industry generated a vast complementary industry of automotive parts manufacturing which continued to be a significant part of the city’s economy for many years despite the loss of automobile manufacturers and the emergence of Detroit as the nation’s automobile capital.

Metal industries had clearly become more diversified by the 1930s. Principal manufacturers included the Akron Surgical House (surgical instruments), the Baur Tack Company (tacks and staples), Central States Bridge and Structural Company (structural steel), (chains and sprockets), Indiana Canning Machine Company (canning equipment), Isley Manufacturing Company (concrete machinery), and Universal Gear Corporation (transmissions, clutches, and machine parts). In the early 1940s the city geared up to meet wartime demands. The Bridgeport Brass facility opened on the city’s west side, producing ammunition for the U.S. Army. ‘s Indianapolis plant manufactured field stoves, aircraft heaters, and bomb detonating mechanisms for the military.

By the 1950s machinery manufacturing and the automotive parts and accessories business were Indianapolis’ leading industries. Important metal-related industries included the Indianapolis Drop Forging Company (tanks and specialty metal products), Sonith Industries (specialty iron castings), heating equipment manufacturers HallNeal Furnace Company and the Peerless Furnace and Foundry, the (transmissions and other aircraft equipment), the Merz Engineering Company (jet aircraft), and Hetherington & Benner (boilers, fabricated structural steel, and road construction equipment such as asphalt mixing machines). City foundries produced steel, iron, copper, brass, magnesium, and aluminum during the decade and more than 160 machine shops were in operation.

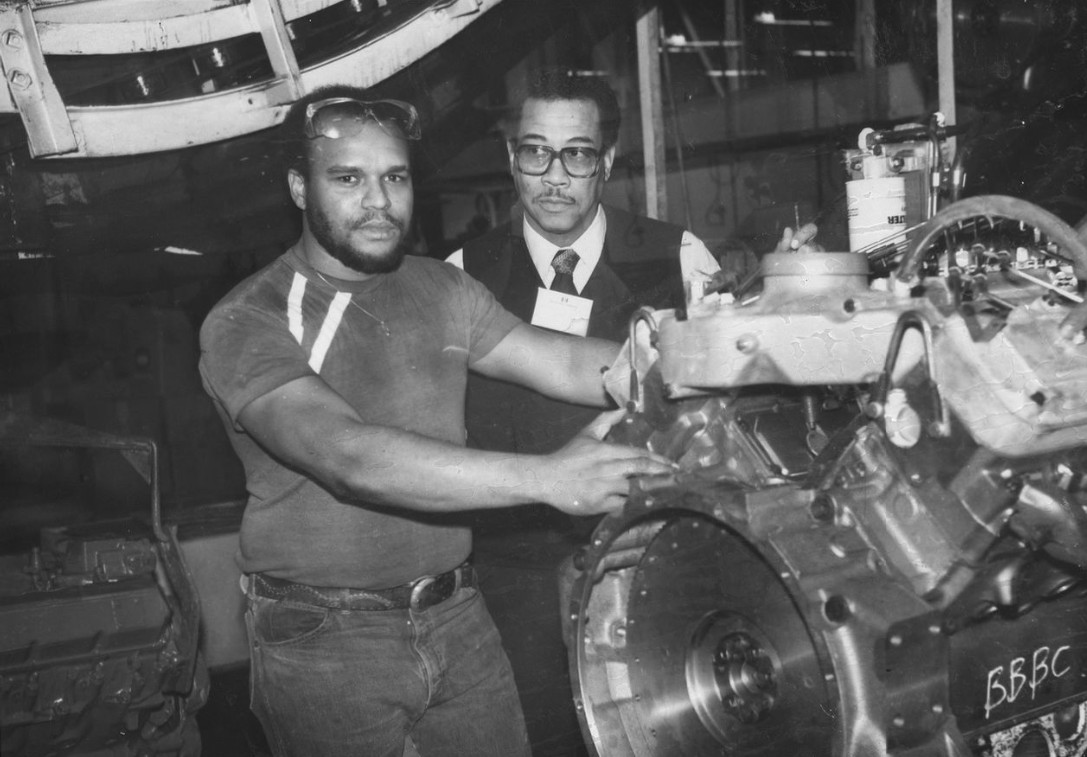

By the 1960s national economic trends strongly affected Indianapolis. National Malleable and Steel Castings closed and hundreds of city residents were out of work. and soon followed. By the early 1980s other large manufacturing facilities in the city had closed, and jobs were lost in the automotive and machine tool industries, although both businesses continued to employ many Indianapolis workers.

As of the early 1990s, important Indianapolis firms involved in metal processing and fabrication included Allison Gas Turbine Operations (gas turbine engines), Allison Transmissions (heavy duty transmissions), GM Truck and Bus Operations (body stamping for trucks), (automotive components), (diesel engines), Carrier Corporation (heating and cooling equipment), Amtrak (rail car maintenance and refurbishing), Chrysler Corporation Foundry (engine blocks), Jenn-Air (ventilating equipment, ovens, ranges), (brass and copper products), Rexnord (chains and bearings), Best Lock (locks), and Diamond Chain Company (roller chains).

*Note: This entry is from the original print edition of the Encyclopedia of Indianapolis (1994). We are currently seeking an individual with knowledge of this topic to update this entry.

Help improve this entry

Contribute information, offer corrections, suggest images.

You can also recommend new entries related to this topic.