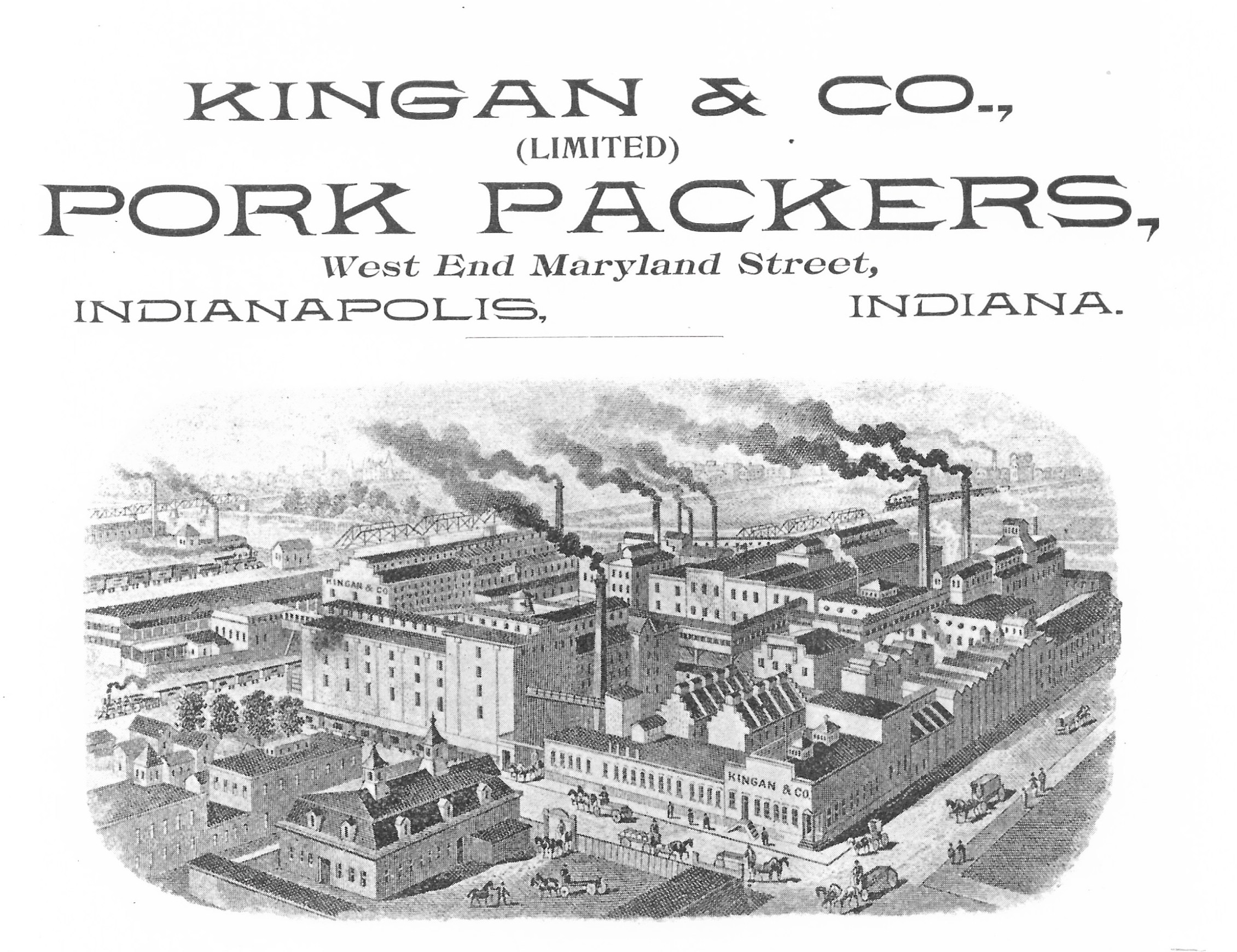

Kingan and Company, a global meatpacking concern, operated at Maryland and Blackford streets along White River. In 1845, Samuel Kingan, a native of Belfast, opened a meatpacking plant in northern Ireland and began a lucrative trade supplying salt pork to British ships. After his meatpacking plants in Brooklyn and Cincinnati burned, he opened an Indianapolis facility in 1862. Thomas Kingan, Samuel’s brother, was the first manager of the Indianapolis plant. In 1875, Kingan merged with another Belfast, Ireland, firm, J & T Sinclair. Family member W. R. Sinclair came to Indianapolis in 1906 and later directed the American operation for 16 years.

Many of Kingan’s original workers were . The company recruited some of them from Ireland. Housing was scarce in the growing Irish community around the plant, so Kingan built an apartment house for workers in 1872 and helped to establish Westminster United Presbyterian Church. Employment at Kingan became a tradition among the city’s Irish American and Eastern European immigrants, with jobs passed from generation to generation.

Since much of the plant’s output was shipped overseas, Kingan adopted a nautical trademark in 1877. It pictured a yellow-slickered pilot at the wheel of an ocean-going clipper ship. For more than 70 years it served as a symbol of the Kingan “reliable” brand. By the 1920s, however, most of the firm’s products went to American consumers, so the company incorporated as a United States concern. Kingan diversified its products and offered a variety of fresh, preserved, and processed meats. Sliced bacon was a new product developed for the American market.

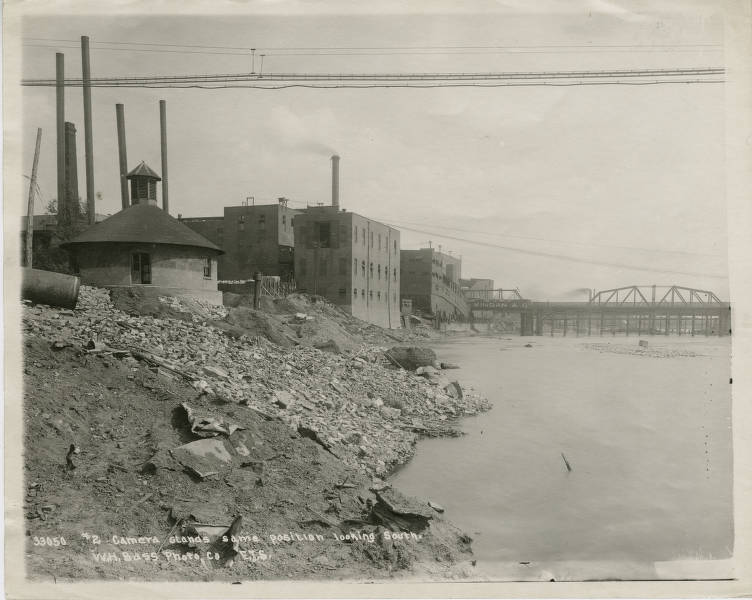

Innovations in meat processing allowed the Indianapolis facility to remain competitive for over a century. The company’s pioneering use of ice to preserve meat allowed year-round operation. Initially the ice was cut from the , but later Kingan manufactured artificial ice. The plant also made use of refrigerated railroad cars to ship fresh products across the country. At the plant, Kingan employees developed new processing techniques, including chain conveyors, moving tables, and on-the-line meat-cutting.

By the time of Kingan’s 100th anniversary in 1945, the Indianapolis facility covered 27 acres and employed 3,000 people. It had grown from a small meatpacking plant to one of the 10 largest in the country. Kingan operated additional plants in several states, including Virginia, South Carolina, Iowa, Nebraska, and Florida.

In 1952, the Hygrade Corporation of Detroit, Michigan, purchased Kingan. Hygrade closed the plant in August 1966, citing increasing costs and low profits. A fire destroyed the vacant plant in 1969 (see ).

Help improve this entry

Contribute information, offer corrections, suggest images.

You can also recommend new entries related to this topic.